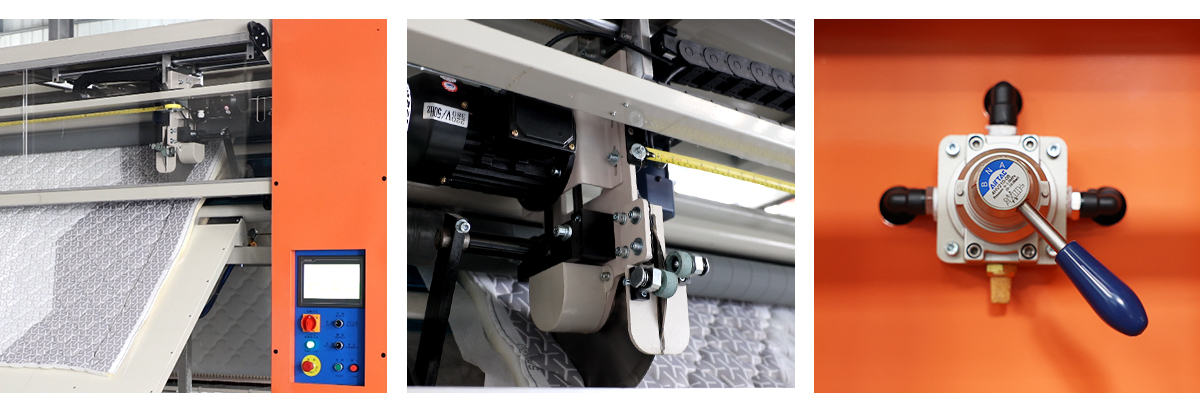

HY-QG-3 Computerized Panel Cutter Machine

Product Description

It is used to crosscut, slitting and edge trimming the quilted fabric, and usually works in tandem with the quilting machine and rolling device ,but it can also run alone.

Technical Characteristics

1. Adopting 7"Panasonic touch-screen , large screen and easy to operate.

2. CE certificate for all the electrical arts used, which greatly guarantees the long life of the machine.

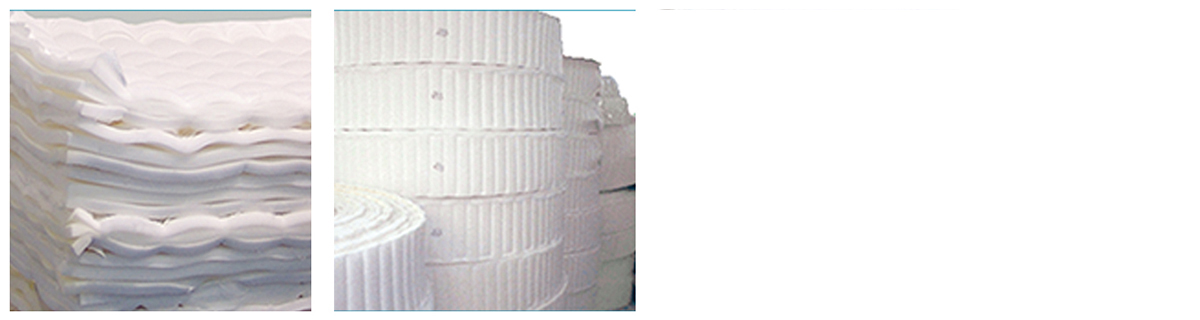

3. Slitter blade equipped with safety protection cover, which further improved the security performance of the machine.

4. Electric controlling for side blade and pneumatic sharpening device, which humanized the operation.

5. Cross cut in one time, which shorten the time for round-way movement of crosscut blade.

6. With thin material detecting devices, sound effects even for processing margin trim of 5mm thickness materials.

7. Rollers adopted with the pneumatic tension device, material rolling will be much quickly and leveling off.

8. Feed-in top snubbed roller adopt toothed synchronous material feeding technology, then the pressure will be even, and feeding will be leveling off...

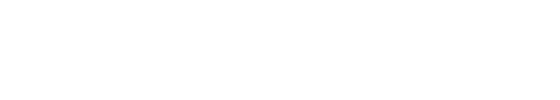

9. The length detecting sensor can be quickly and accurately adjusted through the manual wheel. It is very suitable for those customers who frequently change the length of tailoring.

10. Box-shape machine body, advanced design, precise cutting, higher efficiency.

Detail Pictures

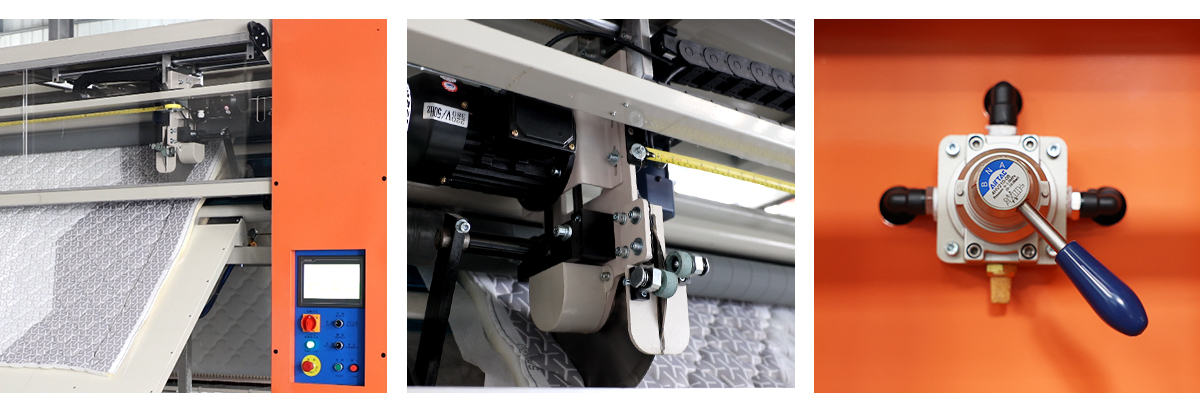

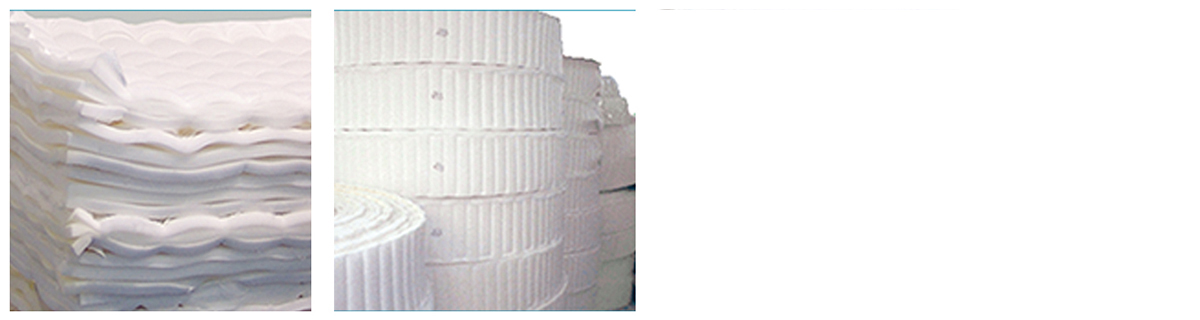

Effect Pictures

Technical Specification

| Model | XDB-QG-3

|

| Trim Margin | The Max. X dimension | 2450mm |

| The Min. X dimension | 1050mm |

| Slitter | The Max. X dimension | 2450mm |

| The Min. X dimension | 60mm |

| Crosscut | The Max. Y dimension | 25000mm |

| The Mix. Y dimension | 800mm |

| Power Supply | 380V/220V 50HZ/60HZ |

| Dimension(L× W× H) | 3750*1330*2365mm |

| Machine Weight | 1500KG |

| Operating Air Pressure | 0.4~0.8Mpa |

| Thickness | 3~80mm |

| Speed | 10m/Min |

| Power | 2KW |