-

Yes. We use world-class brand electrical components, such as Panasonic, Airtac, Mitsubishi, Siemens.

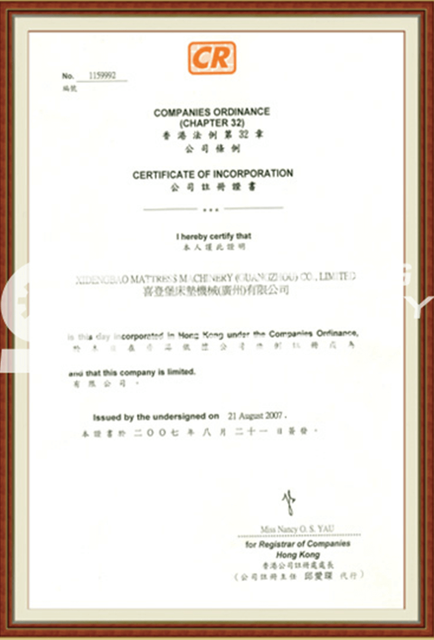

The world famous mattress factories are our customers, for example Simmons, Serta, Sealy. Our products are in line with the world CE certification, the United States Rosh certification, EU UL certification.

-

1: We are the professional manufacturer of smart automatic mattress machine. What's your annual program of mattress? It is bonnell or superlastic? This our design plan of annual output of 50000 mattress before. It is just for reference. And we also pleased that if you any special requirement. Please write a letter of intent purchasing.

2: Yes. You should provide your workshop drawing and investment budget.

3: Absolutely. Please offer your size of workshop(length*width*height). Could you offer graphic model? How much is your budget?

We know nothing because it is the first time of us to produce mattress.(mattress producing process chart)

1: At present, mattress industry is a prosperous industry. Mattress consumption achieved 50000 million all over the world in 2017. You do a sensible choice. We are the first batch enterprises of one of producing mattress machinery in China. After 20-year development, we help some famous brands like Puffy offer perfect mattress machinery producing line projects and help they have a steady development. Therefore, we will make a proper plan for your company according to your request.

2: We can recommend proper machine for you according to your budget. After you buying our equipment, our technicians will help you install machine, have a training and guide you mattress producing technique.

3:Please tell me your budget and output plan, and then we will make whole set project for you.

-

Yes. We have rich experience in production line design and manufacturing. We provide systematic production solutions for mattress manufacturers for years. We can provide you with equipment installation, commissioning and technical training services. We can provide on-site service,after customers’ application, we will send professional after-sales personnel to solve your problem in time

-

1: After installing our machine, we will offer one year warranty and lifetime maintenance.

2: After clients buying our machines, our company can dispatch our technician to install the machines and have a training. Clients needn’t to pay any other serve cost but the fee of technician's visa, air ticket, food and accommodation. Our after-sale serve is lifelong. If there is any problem of your equipment in the later time, our customer service and technician will help you to solve problems.

-

1: Our machine lr-ps-ov, enumerate the advantages... spring output are 120 sets per minute. The machine that you say, which is the same as our product, but the output are 70 sets per minute. Therefore, the price is different.

2: Asking factory according to the specific equipment. For example, our sewing machine. Let He Kai sorts the advantages of our products.

3: Salesmen make a data comparison according to the different machine and then reply to clients.

-

1: We will provide easy-understanding and easy-operating machines, using specification and videos for you. We will arrange remote and field operation training of the machine. We promise that we will teach our clients until they can master the operation of machine.

2: We will give clients installing instruction and accessories drawing when we pack up the machines.

3: We will provide installing instruction, operating video and accessories drawing. And then we will arrange our technician to install and train.

-

We did trade business before, but afterwards, we organized our own researching team for producing sewing series products. Our positioning is being the first brand of sewing machine in China, so we have mastered our core technique. In addition, our company’s core products have a stake in production plant. Our aim is to achieve high standard examination and attain high output standard. Therefore, we are just not a trade company.

-

1: After our technician installing and debugging the machines for clients, we will concern the using situation of machines all the time. We will have return visits one or twice times a year.

2: Our technician finishes the installing program in that country and they will drop in past clients and check their machines.

3: We will visit our clients in a regular time for collecting clients’ feedback. At the same time, in order to serve clients better, we will make marketing surveys for offering proper products for customers.

-

Not yet. But we will consider it in the later time.

-

Of course. Please tell us you visiting schedule and your intentional machine. We will prepare in advance.

-

Yes, our workshop is 50000 square meters. We have 200 workers, our own research team and manufacture center.

-

Yes. Stenburg Mattress Machinery has very rich experience in the design and manufacture of mattress production lines, and can provide more suitable mattress machinery and equipment solutions for customers. For more than 20 years, it has provided systematic production solutions for major mattress manufacturers in the world, and can provide equipment in time Installation and commissioning and technical training services, more technical installers put forward plans and implement them together, so that customers can use them more at ease.

-

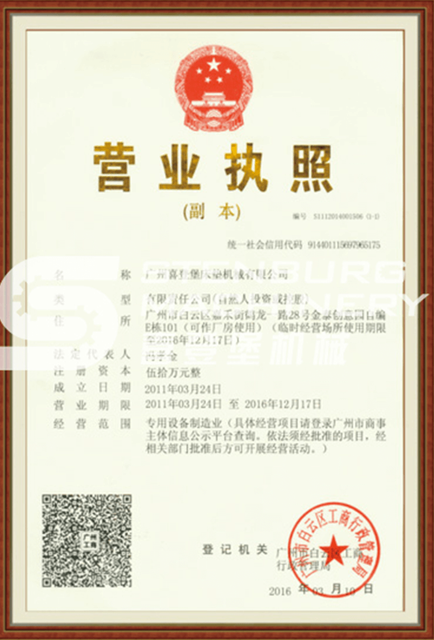

Founded time (1998)

Geographical location (the north gate of China; Guangzhou is the provincial capital of Guangdong, which has convenient sea, land and air traffic and closes to Baiyun Airport. It takes 20 minutes away. )

Positioning (an enterprise which provides whole sets production plan)

Product species (spring, quilting, sewing, tape edge, packing, sponge)

Marketing occupancy (85% home, 80% aboard)

Team scale (20 salesmen, producing technical team has 20 staff)

Research strength (20 independent researching technicians; 10-year researching experience)

Cooperated brands (KINGKOIR, SIMMONS, BOYCELIKS)

Industry leading points (Our sewing machine is the most advanced in China, such as spotting production line, which is beyond the standard of Europe)