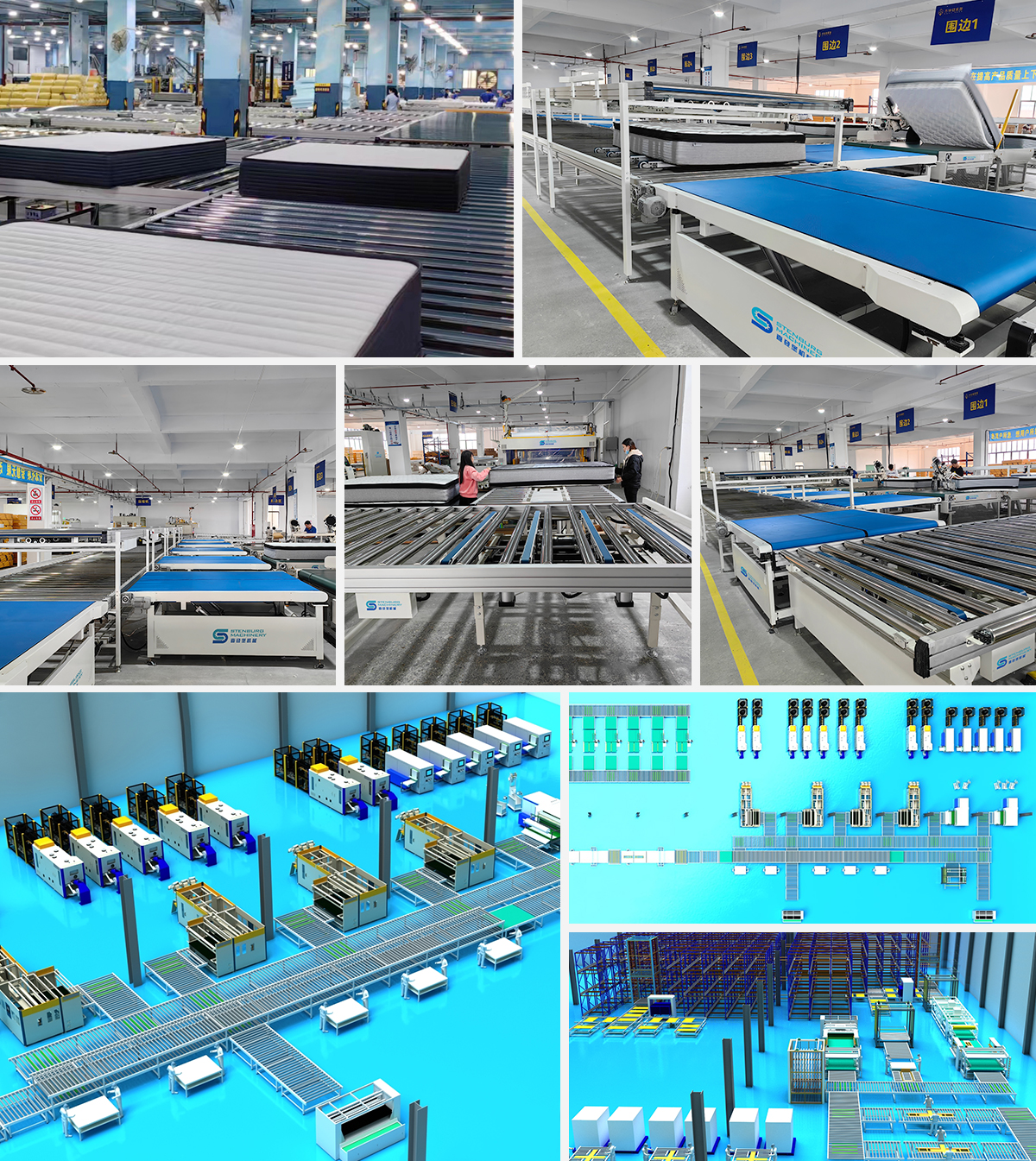

Spring Mattress Production Line![Spring-production-line-detail]()

Product Description

The automatic Simmons mattress production line is mainly used for the automatic conveying and automatic distribution of Simmons mattresses. The automatic mattress production line designed by our company runs smoothly and has high work efficiency, which improves production efficiency and reduces labor and production costs. The process needs to choose different materials to configure the mattress production line, and the production line can be designed according to the customer's factory floor plan.

Technical Characteristics

1. Mechatronics: This machine adopts advanced industrial control technology, all processes are centrally controlled by the PLC system, and can be used with special equipment such as automatic bordering machines and automatic packaging machines to complete the automatic conveying process.

2. The entire production line is fully automatic conveying: using Japan's Mitsubishi PCL as the control core, Japan's Omron sensor as the detection, and Taiwan's Dongli motor as the drive. High-quality pneumatic components, international famous brand low-voltage components, to ensure working reliability.

3. Pneumatic actuator: fast response, high reliability and easy maintenance.

4. Infiltrate the energy-saving design concept: automatic identification of the mattress online when it is in place, and the machine will stop when the transportation is completed.

5. High-quality material production: the use of stainless steel composite pipe material, never rust, to ensure that the surface of the mattress is clean and beautiful. It adopts special aluminum alloy profile protection frame, which is durable and beautiful.

6. Bar code recognition technology: It can cooperate with advanced bar code automatic recognition technology to complete automatic recording and statistics of output, variety classification, and finished product storage.

7. Automatic glue spraying technology: using imported hot melt glue machine and automatic glue spraying manipulator to complete automatic glue spraying, flattening and turning.

Technical Specification

product name | Spring mattress production line |

| altitude | ≤ 1000M |

| Ambient temperature | -5℃ + 40℃ |

| Relative humidity | ≤ 85% |

| No serious corrosive gas in the medium |

| Delivery method | automatic delivery |

| Control mode | Fully automatic PLC control |

| Application | Spring Production Line |

| Equipment capacity | 1000 sheets / day |