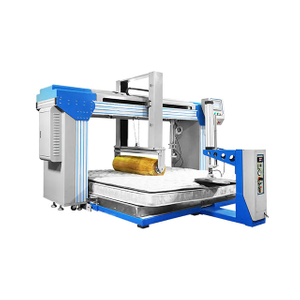

![XDB-F764]()

XDB-F764 Mattress Rolling Test Machine Multi-Function

Product Description

Mattress rolling machines determine the durability of any type of mattress and spring assembly by simulating long-term use conditions, regardless of the material of construction. The rolling stroke can be adjusted according to different mattresses, and the guiding device with low friction coefficient ensures the weight of the entire roller on the mattress. The LCD touch screen display can be easily controlled and set.

Technical Characters

Three functions of mattress curling machine:

1) Durability test

Application and test purpose:

1. The Mattess Durability Tester uses a horizontal hexagonal wooden roller or cylinder (250 mm in diameter at both ends and 300 mm in the middle) to roll back and forth on the mattress to simulate human movement to evaluate the durability of the mattress.

2. The manufacture of the mattress durability tester aims to determine the durability of any type of mattress and spring box unit by simulating long-term use conditions, regardless of its structural materials. It consists of a weighted roller that moves laterally on the test mattress to simulate human movement. By sliding the stroke adjuster to the left or right, the stroke length of the roller movement can be easily adjusted to suit the relevant mattress under test. The Roller can be easily loaded and unloaded onto the test mattress through a motor-driven lifting assembly.

2) EN hardness and height change test

Mattress hardness and height change test application and test purpose:

1. The mattress testing machine combines the loading equipment (roll) with the hardness measurement equipment. Therefore, the hardness test can be performed according to ASTM F 1566 or EN 1957 without rearranging the sample, because the rearrangement of the sample will distort the measured value. It can also display height changes through a servo measuring system.

2. Simply loosen the steel bars of the front frame to insert the sample into the flexible test substrate. This makes the test equipment very effective and space saving.

3. The software allows flexible parameter input, execution of different test procedures, graphical representation of measured values, test evaluation and recording. After reaching the preset number of cycles, the test will end automatically.

3) Edge test

Test standard: EN1725

Application and test purpose:

The machine adds a mattress fatigue test function, which can simulate a human body sitting on the edge of the mattress, and perform 5000 cycles of fatigue testing on the mattress according to EN1725 with a force of 1000N.