![2]() XDB-W-SJ+XDB-QG-3 Computerized Chain Stitch Multi-needle Quilting Machine+Computerized Panel Cutter Machine

XDB-W-SJ+XDB-QG-3 Computerized Chain Stitch Multi-needle Quilting Machine+Computerized Panel Cutter Machine

Technical Characteristics

1.Optimized mechanical structure makes higher speed and more production.

2.More tight thread stitches makes the quilting patterns with stronger three dimensional effect.

3. Needle bar and press plate are controlled by a double.swinging device without cam avoiding lubrication anddirtying of material.

4. Multi-span and independent patterns (360* and 180°patterns are available).

5.Top thread and bottom thread broken detection,automatic needle-lifting, quilting speed set in software.

6.CE Certificate

7.No need to adjust the press plate's position when the thickness of quilting material varies.

8.CAD drawing methods enable precise, convenient, and efficient graphics creation

9.The new generation of controlling system guarantees quilting accuracy,Parameters or patterns do not require excessive modification during quilting process

10.Strong functions of pattern-combining and multi-spanquilting to enable you to quilt different patterns in each row in the mattresses of different sizes

11.Status monitoring provides a clear view of the machine's operational condition.

12.10”touch screen, large screen for ease of operation

13.Slitting blades equipped with safety protection covers,more convenient and safer

14.Electric controls for length cutting blade and pneumatic sharpening device

15.With thin material detecting devices, sound effects even for processing margin trim of 5mm thickness materials.

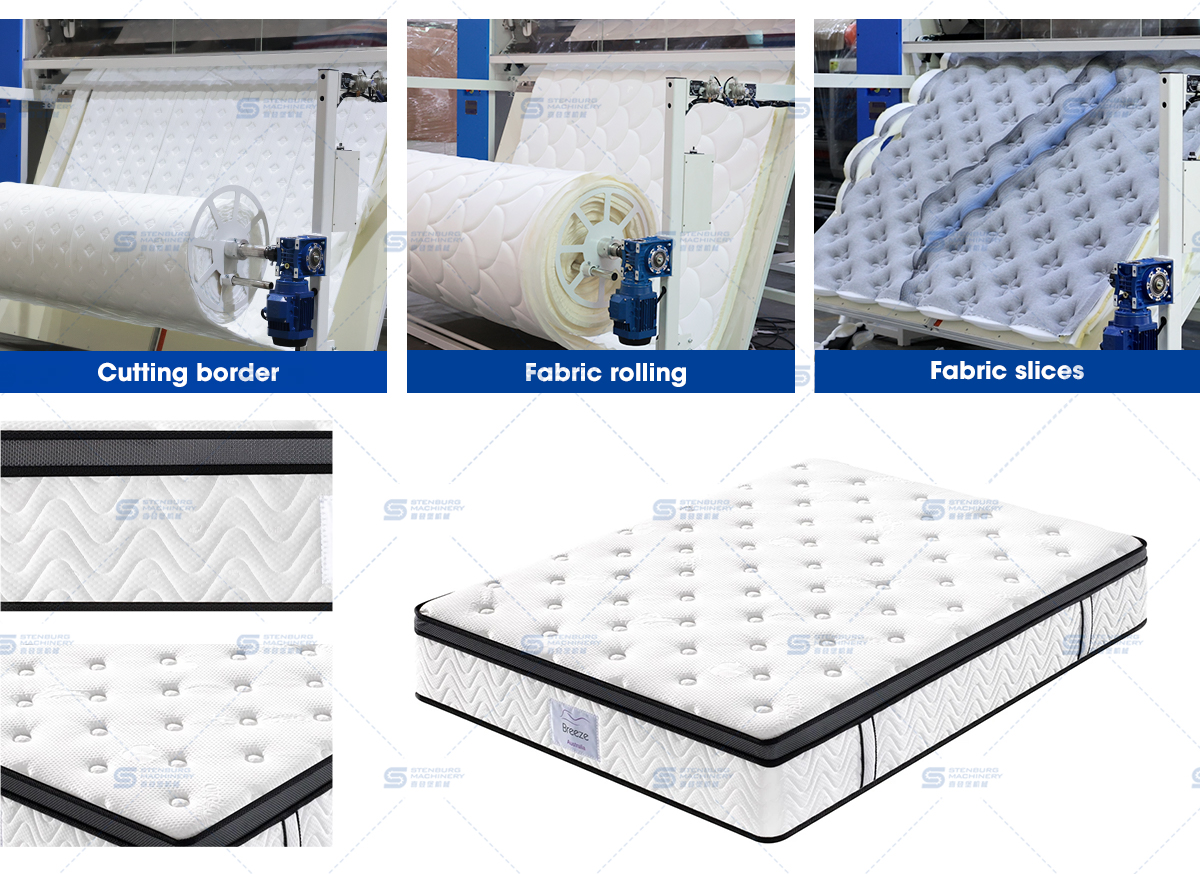

Detail Pictures

![细节图]()

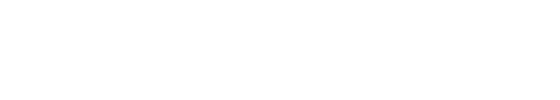

Effect Pictures

![效果图]()

Technical Specifications

| Model | XDB-W-SJ |

| Machine size | L4795xW1670xH2050 mm |

| Quilting width | 2450mm |

| Thickness of quilting | ≤80mm(for all patterns) |

| Stitch length | 3~8mm |

| Speed of operation | 60~300 m/h |

| Quilting speed | 600~1200 RPM |

| Total power required | 7KW |

| Voltage | 380V/50HZ、220V/60HZ |

| Gross weight | 5000KG |

| Model | XDB-QG-3 |

| ( Edge trim ) The Max. X dimension | 2450mm |

| ( Edge trim ) The Min.X dimension | 1050mm |

| ( Slitters ) The Max. X dimension | 2450mm |

| ( Slitters ) The Min. X dimension | 45mm |

| ( Cross cut ) The Max. Y dimension | 2500mm |

| ( Cross cut ) The Min. Y dimension | 800mm |

| Machine size | L3750×W1330×H2365mm |

| Weight | 1500KG |

| Operating air preasure | 0.4~0.8(Mpa) |

| Thickness | 3~80mm |

| Speed | 7.5m/min |

| Power | 2KW |

| Power supply | 380V/50HZ、220V/60H |

XDB-W-SJ+XDB-QG-3 Computerized Chain Stitch Multi-needle Quilting Machine+Computerized Panel Cutter Machine

XDB-W-SJ+XDB-QG-3 Computerized Chain Stitch Multi-needle Quilting Machine+Computerized Panel Cutter Machine